-

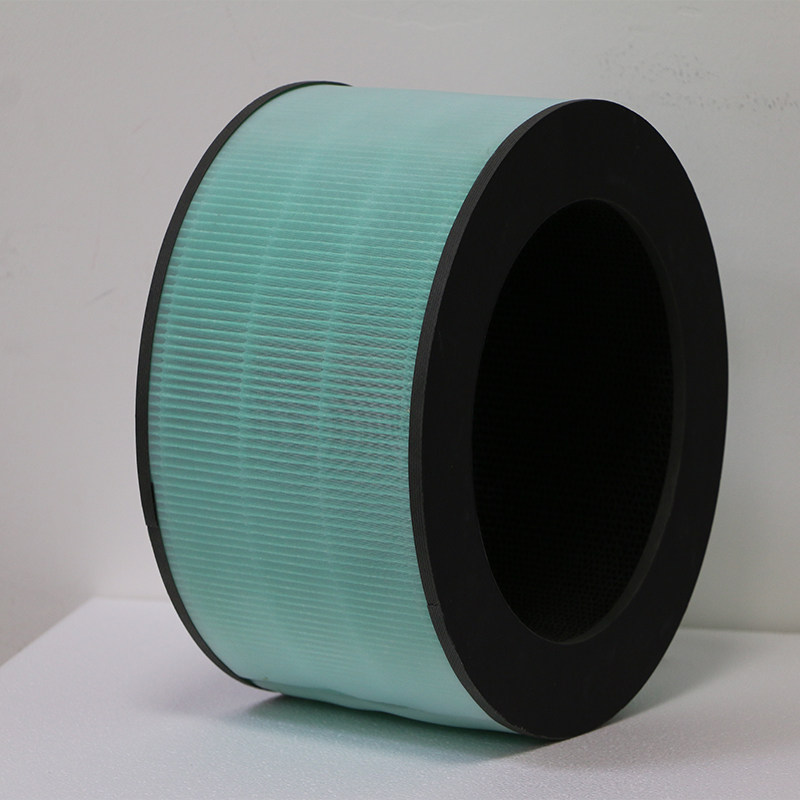

High-efficiency composite material for Indoor Air Filter

By using imported high melt flow rate PP raw materials, after melt spinning, a deep micro/meso-level interconnected porous structure is formed. Simultaneously, special polarizable substances are added inside the fibers, and through a unique polarization process, the stability of charges and the strong surface electric field between the fibers are achieved. This technology not only does not increase air resistance but also exhibits a highly effective electrostatic adsorption effect on fine particles in the air. It can effectively filter out dust, hair, and other airborne particles.

-

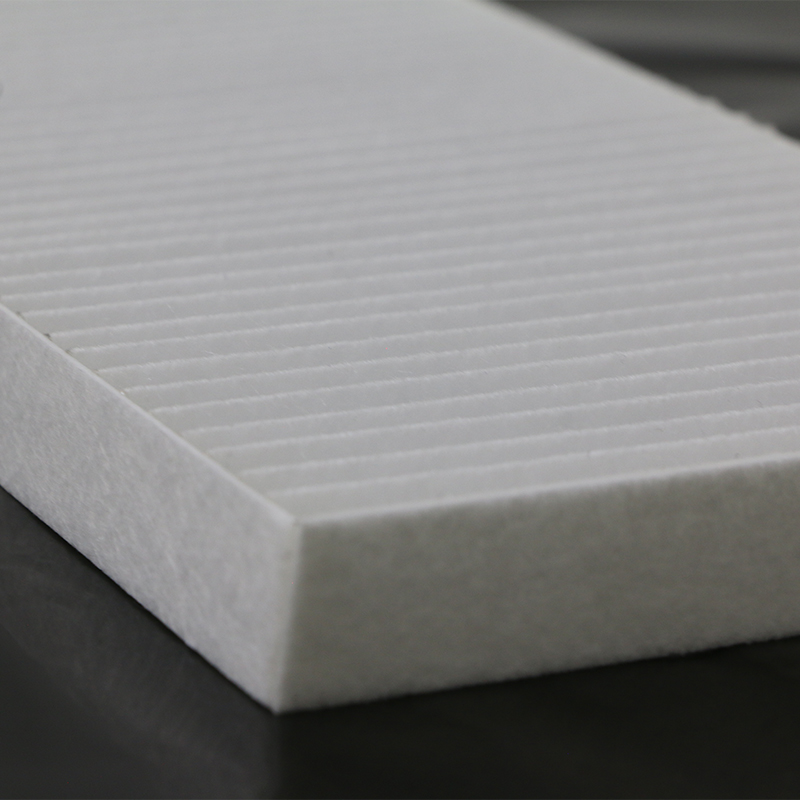

Material for Cabin Filter

In daily life, the air quality inside vehicles is often overlooked. However, the air pollutants inside the car can significantly impact both driving experience and health. We utilize electrostatic adsorption filtration technology to achieve efficient filtration while maintaining extremely low air resistance. This technology effectively filters out tiny particles such as dust, pollen, and bacteria in the air, ensuring fresh and clean air inside the car. It allows you and your family to enjoy a more comfortable and healthy environment during your journeys.

-

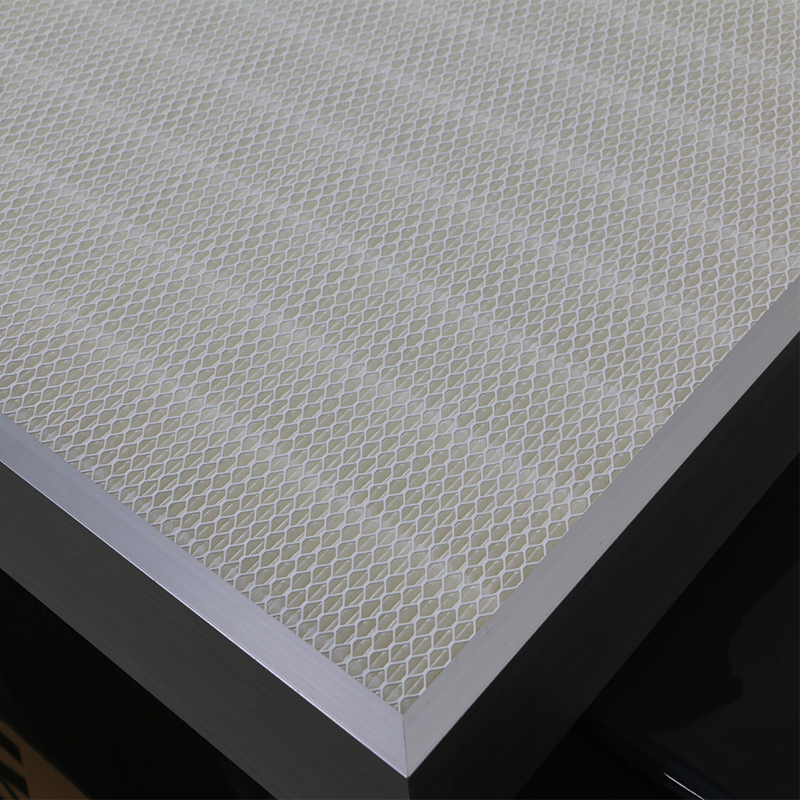

Filtration Material for Industry

In industrial applications, primary filters are mainly divided into two forms: panel filters and bag filters. They are commonly used for air pre-filtration in cleanrooms, as well as fresh air and air conditioning systems, to remove larger particles, impurities, and dust contaminants, thereby protecting higher-level filters. Our company’s products are characterized by high dust holding capacity, low resistance, stable efficiency, and cost-effectiveness. They are widely applied in cleanrooms of industries such as semiconductors, biopharmaceuticals, and food processing.

SEARCH